I have spent the last week or so experimenting with some ways to machine and cast foam props for LARPers and Cosplayers with my friend Jesse. Jesse makes these props by hand, and has some really good tutorials on making them, but we wanted to see just how much we could do by using the Laser cutter and CNC Mill at the SODO MakerSpace.

Here are a few photos of what we have been working on.

We need better mold, but not bad.

Prepping our test mold.

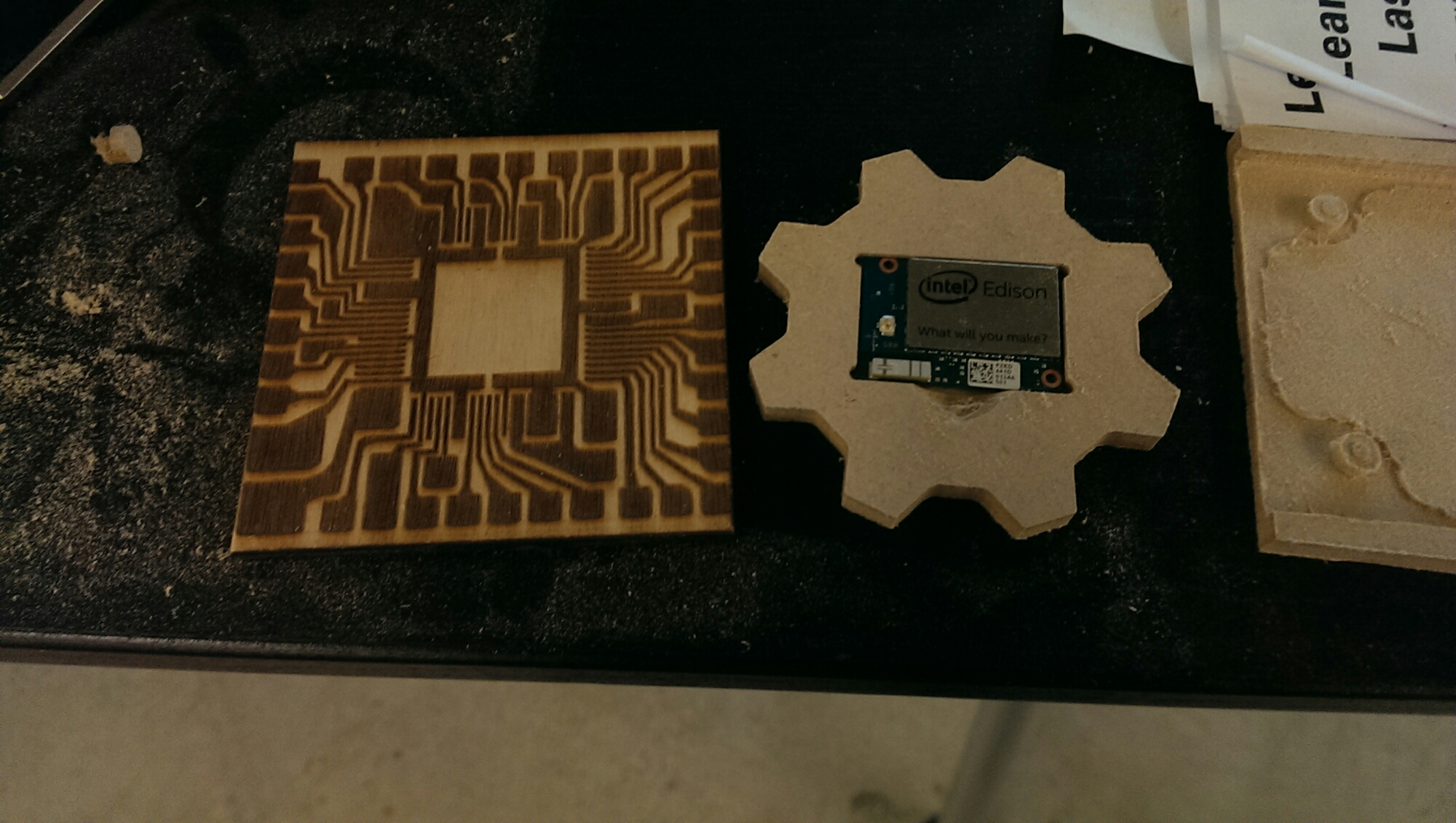

Laser cut bolt

Working out some details.

Bolt design for the laser cutter

Smooth-On’s Flex Foam-iT 17

Trying to make a mold with my new vacuformer.

Laser cut bolts

Laser cutting bolts

Some Demolding spray.

Trying to make a mold with my new vacuformer.

Smooth-On’s Flex Foam-iT 17

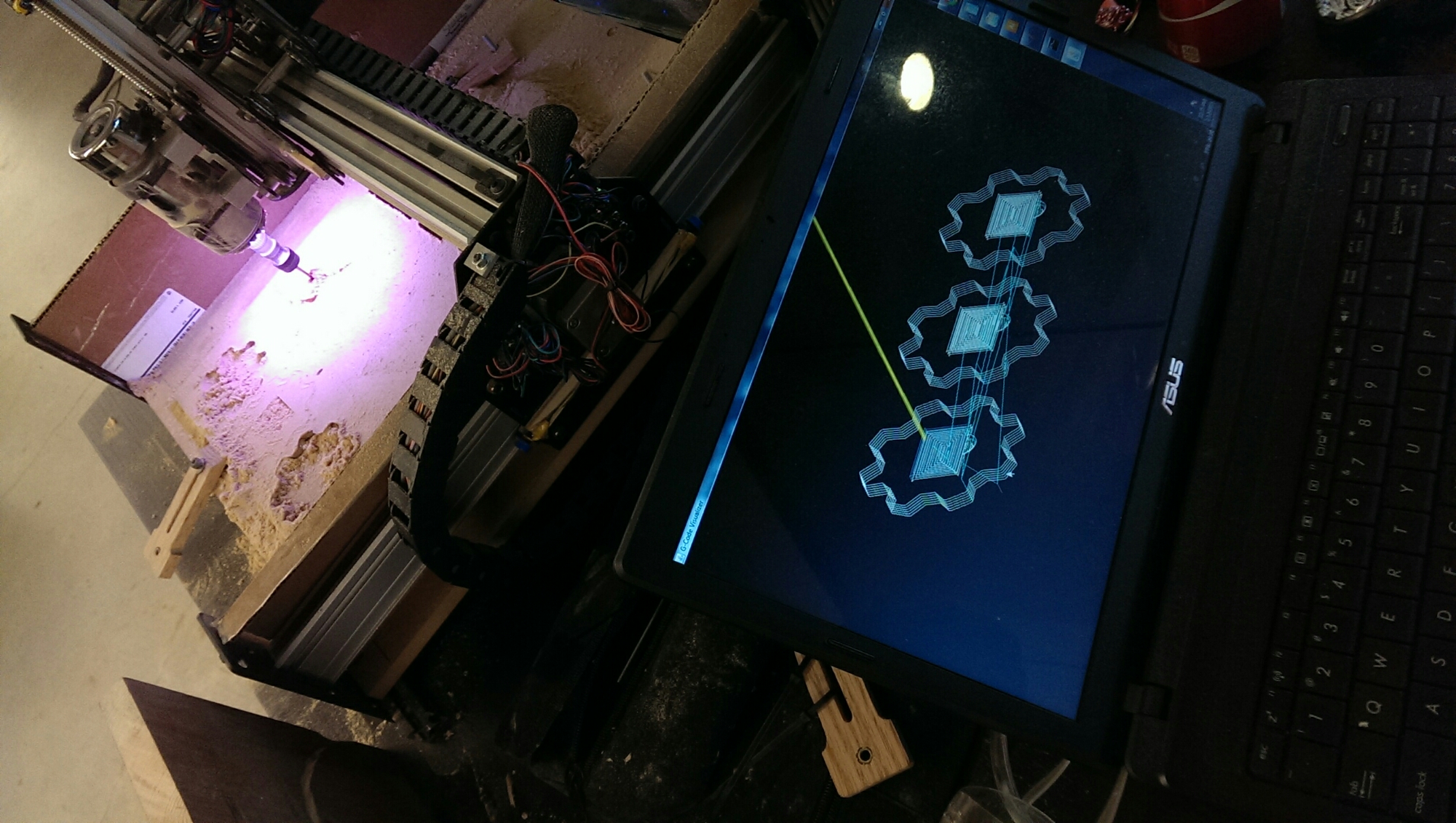

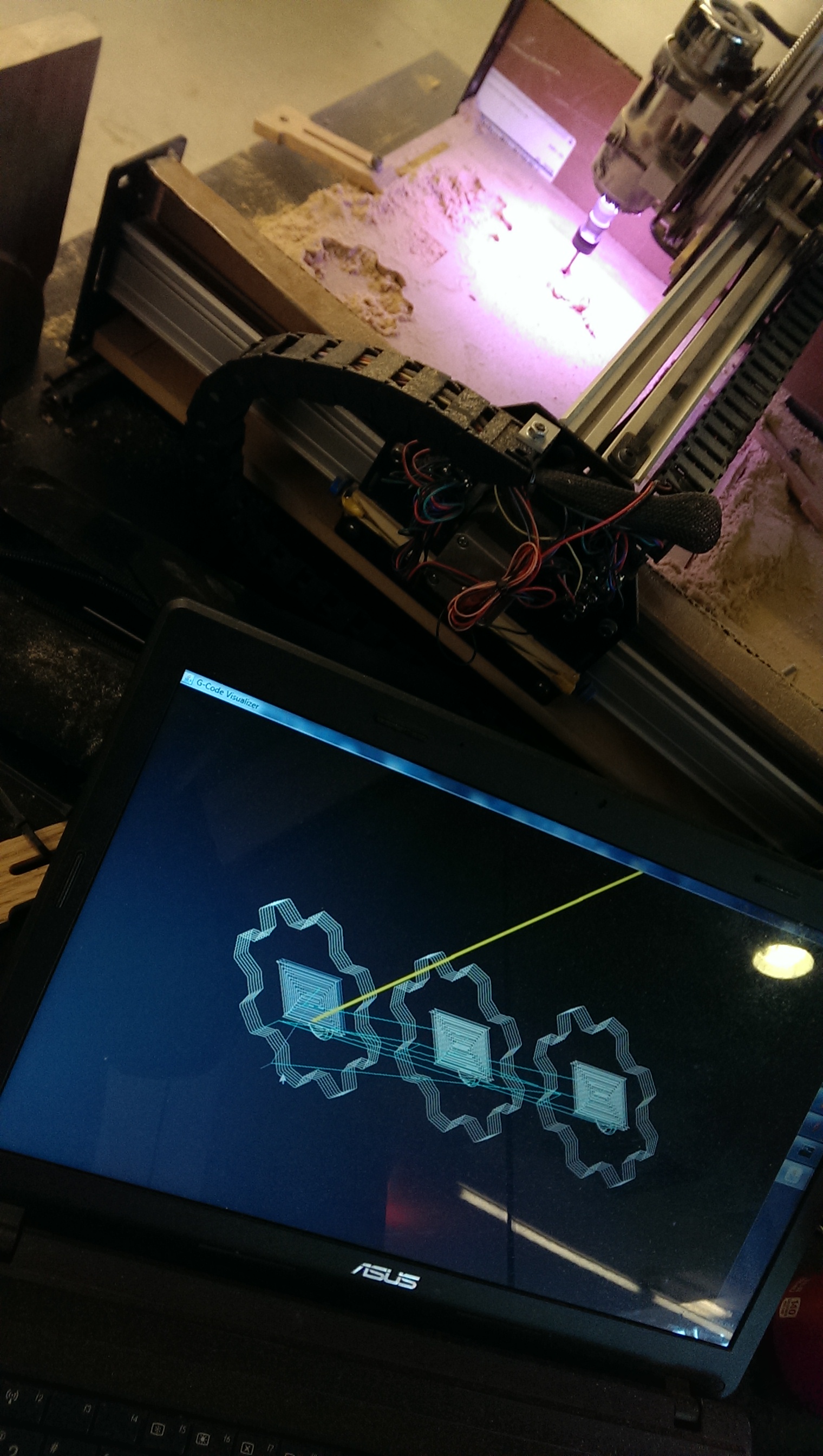

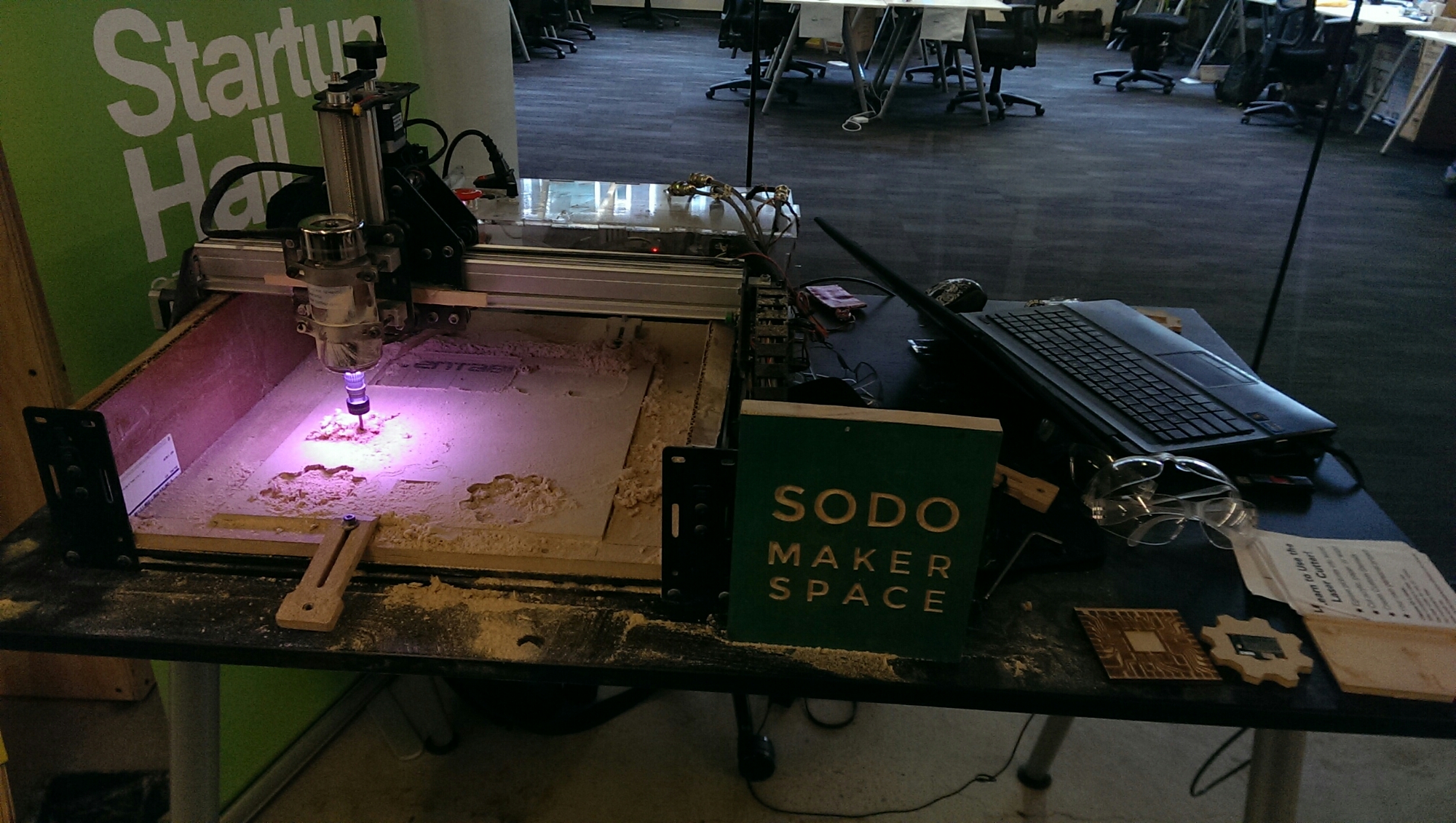

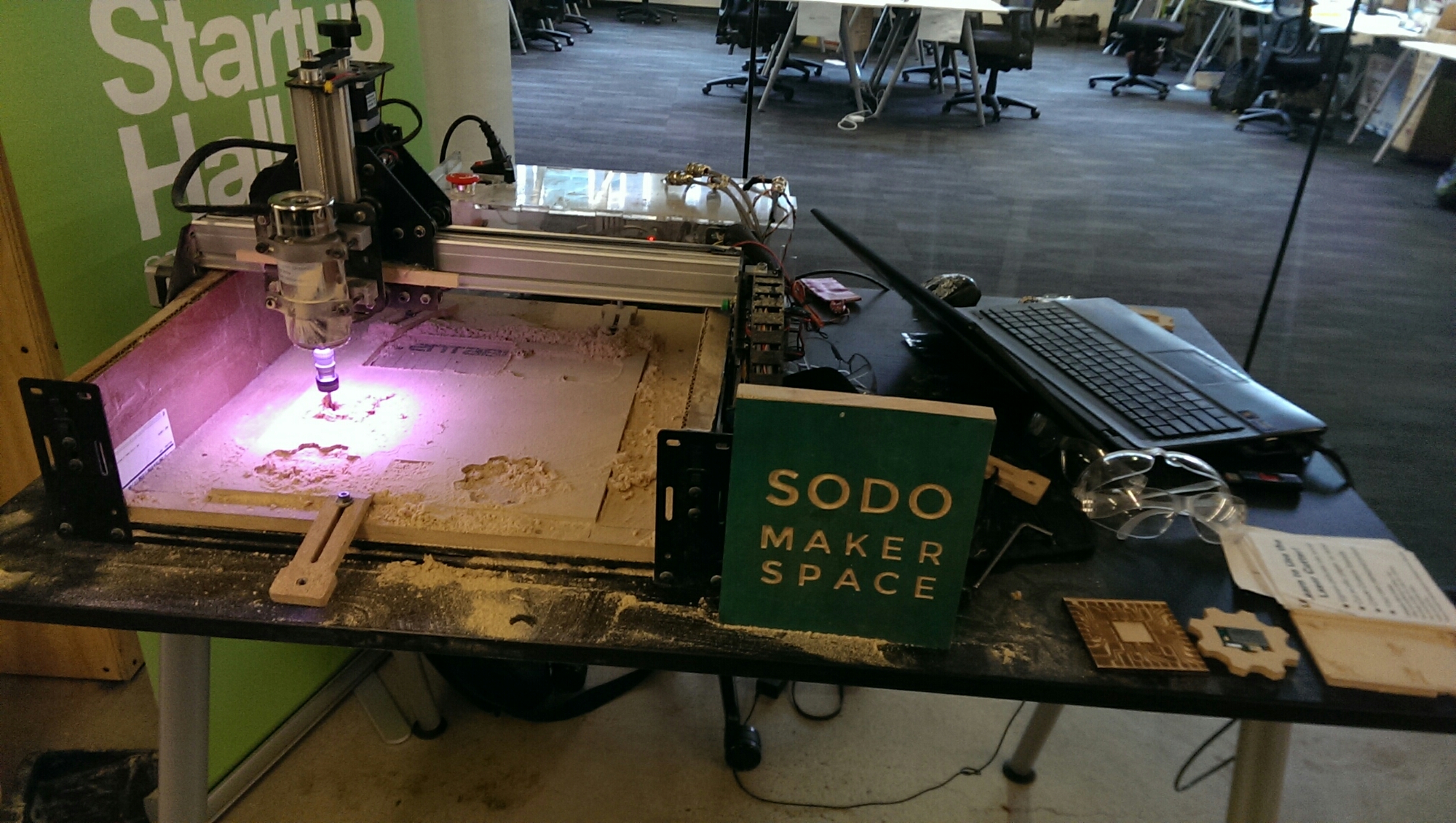

Trying out a CNC path for bolts.

Cut out the Flex Foam test wrench

Trying to make a mold with my new vacuformer.

Testing the Flex Foam

Our prototype wrench

Redesigning the wrench for the laser cutter

Our prototype wrench

Our Flex Foam test wrench.

Our prototype wrench

The laser cutter

Pouring the Flex Foam.

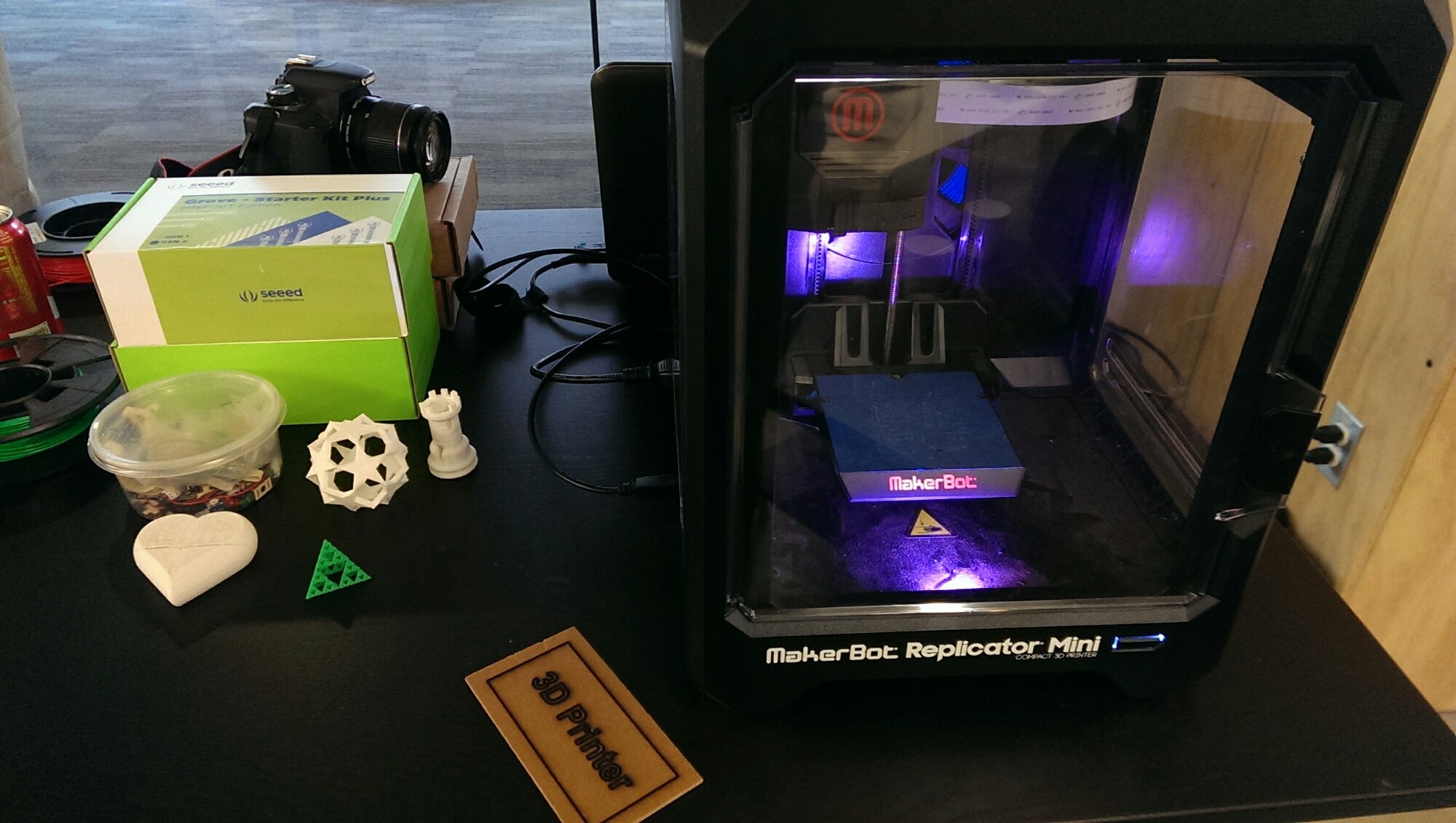

SODO MakerSpace sign.

Testing the Flex Foam

We figured out that doing the wrench on the CNC mill would take to long.

Testing the Flex Foam

The laser cutter

Pouring the Flex Foam.

Smooth-On’s metallic surface powder.

Working out the core pocket.

Bolt design for the laser cutter

Testing the Flex Foam

Testing the Flex Foam

Smooth-On’s Flex Foam-iT 17